Civil Engineering & Geotextile

Non Woven Geotextile Fabric: Benefits, Applications, and Buying Guide

Non Woven Geotextile Fabric: Benefits, Applications, & Buying Guide. Discover the benefits & applications of non woven geotextile fabric! Our easy buying guide helps you choose the right non woven geotextile fabric for your needs.

<<<<< Buy Now from Official offer >>>>>

What is Non Woven Geotextile Fabric?

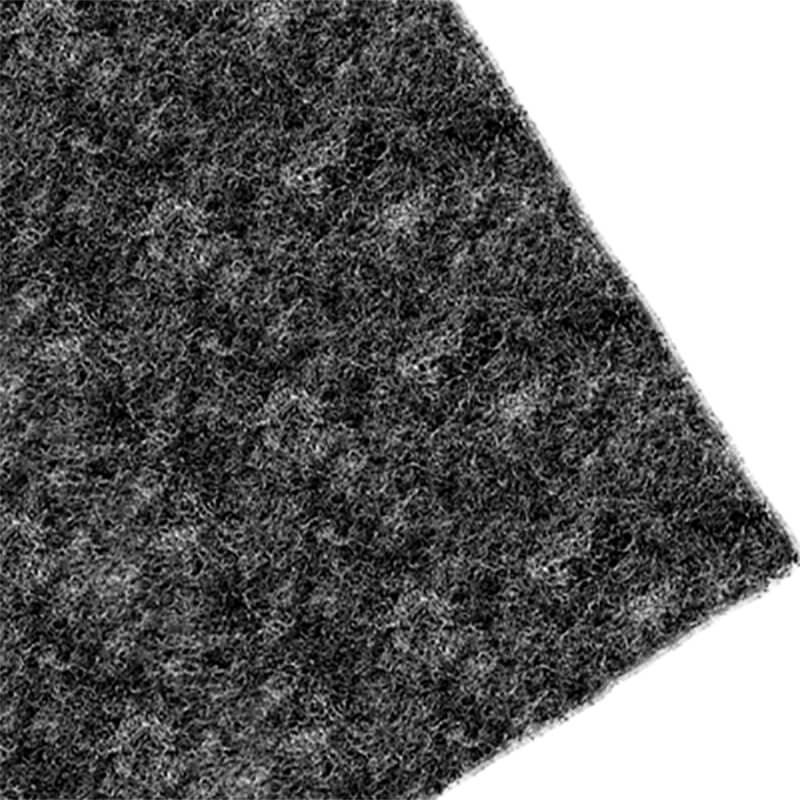

Non woven geotextile fabric is a type of synthetic fabric made from fibers that are bonded together using chemical, mechanical, or thermal processes. Unlike woven fabrics, non woven fabrics do not involve interlacing threads. This results in a material that can have enhanced drainage & filtration capabilities, making it suitable for various applications in construction & landscaping. The production process permits flexibility in design, thickness, & other properties, catering to specific project needs.

These fabrics offer advantageous qualities like high permeability & resistance to UV light. They are used in applications ranging from road construction to erosion control. The versatility of non woven geotextile fabric makes it a popular choice among builders & engineers. Its adaptability makes it suitable for various soil types, providing added support, stability, & durability in diverse conditions.

Non Woven Fabric for Filtration

Benefits of Using Non Woven Geotextile Fabric

There are numerous benefits associated with using non woven geotextile fabric in various applications. Some of the most notable advantages include:

- Filtration Properties: It allows water to pass while filtering out soil particles, preventing sediment accumulation.

- Prevent Soil Erosion: The fabric helps retain soil in place, reducing erosion caused by wind & water.

- Drainage Improvement: Excellent drainage capabilities that prevent the pooling of water.

- Durability: Resistant to chemicals, UV rays, & temperature fluctuations.

- Cost-Effective: Offers significant savings in maintenance & repair costs over time.

These benefits make it an invaluable resource for projects requiring soil stabilization & drainage control. Using non woven geotextile fabric provides enhanced performance for both temporary & permanent installations. This durability also contributes to long-term sustainability in various construction projects.

Applications of Non Woven Geotextile Fabric

Non woven geotextile fabric has extensive applications across several industries. It is particularly prevalent in civil engineering, landscaping, & environmental projects. Some key applications include:

| Application | Description |

|---|---|

| Drainage Systems | Used to filter soil & allow water to pass, enhancing drainage. |

| Erosion Control | Protects soil from erosion on slopes & around structures. |

| Road Construction | Used as a layer in roadbeds to provide stability & support. |

| Retaining Walls | Reduces pressure against the wall by facilitating water drainage. |

These applications show how versatile & essential non woven geotextile fabric is in engineering projects. Its ability to adapt to various environments makes it suitable for use in roads, drainage systems, & landscaping.

How to Choose the Right Non Woven Geotextile Fabric?

Choosing the right non woven geotextile fabric depends on various factors. Here are some steps that can guide you in making a decision:

- Assess the Soil Type: Determine whether the soil is sandy, clayey, or rocky. Different fabrics work better with different soil types.

- Understand the Project Needs: Identify whether the primary requirement is drainage, filtration, or erosion control.

- Weight & Thickness: Choose the appropriate weight & thickness based on project specifications.

- Consult with Professionals: Seek advice from engineers or suppliers to find the right material.

Each factor directly influences the performance of non woven geotextile fabric in its intended application. Consulting with seasoned professionals can also save significant time & cost. They can guide choices especially in specialized applications. Being equipped with the right information will lead to a successful project outcome.

Installation Process for Non Woven Geotextile Fabric

Proper installation of non woven geotextile fabric is critical for maximizing its effectiveness. Here’s a step-by-step guide:

- Site Preparation: Clear the area of vegetation, rocks, & debris.

- Lay the Fabric: Unroll the fabric on a flat surface, ensuring it covers the entire area.

- Overlap Edges: When joining multiple pieces, overlap the edges by at least 12 inches.

- Secure the Fabric: Use stakes or pins to hold the fabric in place, especially on slopes.

- Add the Drainage Layer: Install gravel or soil over the fabric, ensuring that it remains optimal.

Correct installation increases the performance of non woven geotextile fabric & prevents movement or damage. It’s essential to follow these steps to ensure that the fabric lasts & performs effectively in the given conditions.

Cost Considerations for Non Woven Geotextile Fabric

When budgeting for a project involving non woven geotextile fabric, you should consider several factors that can influence cost. These include the type of fabric required, the total area to be covered, & any additional installation expenses.

Here’s a basic cost breakdown:

| Factor | Estimated Cost |

|---|---|

| Fabric Price per Square Foot | $0.50 – $3.00 |

| Shipping Costs | Varies by location |

| Installation Costs | $1.00 – $5.00 per square foot |

Understanding these costs helps in planning your budget more effectively. On top of that, investing in quality non woven geotextile fabric pays off in terms of durability & performance.

Environmental Impact of Non Woven Geotextile Fabric

The use of non woven geotextile fabric can have significant benefits for the environment. It aids in soil preservation, reduces debris runoff, & enhances water quality. Here are notable benefits:

- Soil Conservation: Protects soil from erosion & degradation.

- Improved Water Quality: Filtrates pollutants, preventing contamination of water bodies.

- Supports Environmental Projects: Essential in land reclamation & restoration projects.

The overall impact increases sustainability while providing essential support for various landscapes. By utilizing non woven geotextile fabric, you contribute positively to environmental efforts, promoting better land management practices.

Personal Experience with Non Woven Geotextile Fabric

I recently had the opportunity to use non woven geotextile fabric in a landscaping project. It was crucial for soil stabilization around several flower beds. The fabric helped to filter water effectively & prevent erosion during heavy rains. I noticed an immediate difference in the drainage capacity of the area.

It became easier to maintain the landscaping, & the plants thrived without the fear of soil degradation. I highly recommend its usage for anyone looking to improve their outdoor spaces.

Conclusion: Making an Informed Decision

Choosing the right non woven geotextile fabric can lead to better project outcomes. Evaluate your needs based on the applications mentioned. Consulting experts is crucial for effective selection & installation.

As Julia Roberts once said,

“Quality materials make all the difference in a project.”

Focusing on quality not only ensures durability but also enhances performance.

By following the guidelines in this post, you now have the tools to select the right fabric for your project needs. Making informed decisions will help you achieve the desired results efficiently.

<<<<< Buy Now from Official offer >>>>>

Woven vs Nonwoven Geotextile Fabric | Choosing the Correct Geotextile for Your Project

Non Woven Geotextile Fabric: Benefits, Applications, & Buying Guide

Non Woven Geotextile Fabric: Benefits, Applications, & Buying Guide

Feature of Non Woven Geotextile Fabric

Non woven geotextile fabric offers unique features that make it a preferred choice in various applications. These fabrics are predominantly made from synthetic fibers, bonded together using mechanical, thermal, or chemical processes rather than woven. This leads to numerous advantages:

- High permeability for effective drainage.

- Good soil erosion control properties.

- Lightweight & easy to transport.

- Durability & resistance to environmental degradation.

- Versatile usage in civil engineering & landscaping projects.

This fabric type also excels in filtration, allowing water to pass through while retaining soil particles. And another thing, its ability to adapt to various climates enhances its applicability in different conditions.

Another significant feature is its cost-effectiveness compared to woven geotextiles. This affordability coupled with its functionality makes it a popular choice for contractors & engineers.

Challenges of Non Woven Geotextile Fabric

While non woven geotextile fabric has many benefits, users may face some challenges. One common issue is compatibility with specific soil types. Certain installations may require additional testing to determine the best fabric type for the job.

Feedback from users often indicates difficulties in selecting the right thickness & strength. Variability in manufacturer specifications can lead to confusion. Without proper guidance, users may purchase fabrics that do not meet their project requirements.

On top of that, some users report that installation can pose a learning curve. Without prior experience, understanding how to properly lay the fabric may require additional time or professional assistance. Suggestions for overcoming these hurdles include consulting with suppliers & utilizing resources like installation manuals or videos.

Price of Non Woven Geotextile Fabric

Pricing for non woven geotextile fabric varies based on factors such as material grade, thickness, & manufacturer. The following table illustrates typical pricing for a range of fabric types:

| Fabric Type | Thickness (mm) | Price per Yard ($) |

|---|---|---|

| Standard Non Woven | 3 | 0.50 |

| Heavy Duty Non Woven | 5 | 0.80 |

| High Performance Non Woven | 10 | 1.20 |

Prices can fluctuate based on local demand, supplier costs, & manufacturing advancements. Bulk purchases often yield discounts. Hence, researching multiple suppliers could lead to significant savings.

Limitations of Non Woven Geotextile Fabric

Despite its advantages, non woven geotextile fabric has limitations. One primary concern is its UV resistance, as prolonged exposure can weaken the material. While many products are treated to resist degradation, it’s essential to check manufacturer specifications.

Another limitation is its potential for higher permeability, which may not be ideal for every application. In some cases, the need for enhanced filtration or stronger barriers could lead users to prefer woven alternatives. Thus, users must carefully assess project needs before selecting the fabric type.

On top of that, recycling options for non woven materials are limited. Many consumers increasingly prioritize eco-friendly products, making this aspect important to consider when choosing materials.

Case Studies

Real-life examples illustrate the effectiveness of non woven geotextile fabric. A construction site in California utilized heavy-duty non woven fabric for erosion control on a hillside project. The installation resulted in minimized soil runoff & preserved vegetation.

Another study involved a landscaping project where the fabric was used for drainage around a new property development. Users reported that the fabric allowed for efficient water management while maintaining soil structure. Overall, the project achieved significant cost savings due to reduced erosion repair costs.

In a highway construction project, non woven geotextile fabric was employed to stabilize the roadbed. The result was a more robust foundation that minimized maintenance over time. Feedback from engineers highlighted the fabric’s ease of installation as a key benefit.

Recommendations for Non Woven Geotextile Fabric

<pTo maximize the benefits of non woven geotextile fabric, several recommendations are worth considering:

- Conduct soil analysis before selection.

- Choose the appropriate fabric thickness based on application.

- Consult supplier technical data for specific projects.

- Follow manufacturer installation guidelines closely.

- Regularly inspect fabric performance in installations.

Implementing these strategies can enhance user experience & project results. Advanced users may consider combining the fabric with other materials for improved performance. For example, placing gravel over the fabric can enhance drainage effectiveness.

Key Aspects of Non Woven Geotextile Fabric

When assessing various options, focus on these crucial aspects:

- Water permeability rates & soil retention capabilities.

- Durability in various environmental conditions.

- Manufacturing details, including compliance with standards.

- Feedback & reviews from previous users.

Analyzing these factors can lead to better purchasing decisions & project outcomes. Understanding specific project requirements also aids in selecting the right fabric type.

Applications of Non Woven Geotextile Fabric

Non woven geotextile fabric serves a multitude of applications across industries. Its versatility is a key selling point:

- Erosion control in civil engineering projects.

- Filtration in drainage systems.

- Geothermal applications for ground stabilization.

- Landfill liners for waste containment.

- Asphalt overlay for reinforcements.

These applications highlight the importance of selecting the right fabric type based on individual project needs. Engineers often recommend testing small samples for performance evaluation.

Market Trends in Non Woven Geotextile Fabric

Recent trends indicate a growing demand for non woven geotextile fabric in green construction practices. Sustainability emphasizes recycling & reusing materials, affecting buyer preferences in the industry.

Innovation in manufacturing processes also leads to the development of more durable materials. Suppliers are responding to market needs by offering biodegradable options that cater to environmentally conscious projects.

In urban areas, the increase in landscaping & drainage projects is driving further demand. Landscape architects frequently rely on non woven fabrics for optimizing water management solutions.

Conclusion

Exploring the myriad of features & applications, non woven geotextile fabric proves to be a valuable addition to construction & landscaping projects. Users must keep informed about market trends & product variations to make effective choices.

What are non woven geotextile fabrics?

Non woven geotextile fabrics are versatile materials made from synthetic fibers that are bonded together through chemical, mechanical, or thermal processes. They serve various purposes in civil engineering, landscaping, & construction applications.

What are the main benefits of using non woven geotextile fabrics?

These fabrics offer several advantages, including excellent filtration, separation, & drainage properties. They are also lightweight, easy to install, & resistant to biological degradation, making them suitable for long-term use.

In what applications are non woven geotextile fabrics commonly used?

Non woven geotextile fabrics are commonly used in road construction, erosion control, drains, landfill liners, & as a protective layer in various landscaping projects.

How do non woven geotextile fabrics contribute to soil stabilization?

These fabrics help in soil stabilization by providing separation between soil layers & preventing the mixing of different materials. They enhance load distribution & improve the overall strength of the soil structure.

Can non woven geotextile fabrics be recycled?

Many non woven geotextile fabrics are made from recycled plastics & can be recycled after their use. This contributes to environmental sustainability & waste reduction.

What factors should be considered when buying non woven geotextile fabrics?

When purchasing these fabrics, consider factors like texture, weight, material composition, porosity, & specific application requirements to ensure you choose the right type for your project.

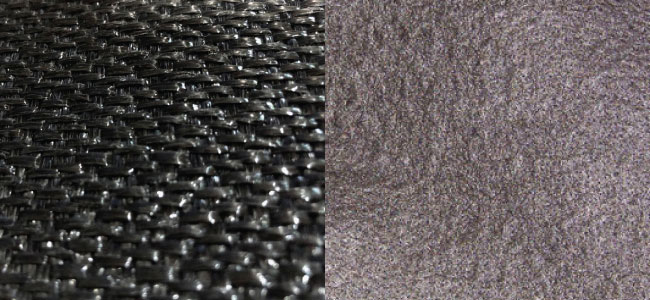

How do non woven geotextile fabrics differ from woven geotextiles?

Non woven geotextiles are made from randomly arranged fibers, while woven geotextiles consist of interconnected fibers or yarns. This difference results in variations in properties like strength, drainage, & flexibility.

What installation methods are recommended for non woven geotextile fabrics?

Installation methods can vary based on the application but commonly include laying the fabric flat, overlapping seams, & securing edges with staples or stakes to prevent movement.

Are non woven geotextile fabrics resistant to UV rays?

Many non woven geotextile fabrics offer UV resistance, which helps to prolong their lifespan in outdoor applications. Be that as it may, checking manufacturer specifications is recommended for specific UV ratings.

How can non woven geotextile fabrics impact drainage systems?

These fabrics enhance drainage systems by allowing water to flow through while filtering out particles & sediments. This helps maintain clear drainage pathways & prevents clogging.

<<<<< Buy Now from Official offer >>>>>

Conclusion

In summary, non woven geotextile fabric is a versatile material offering numerous benefits. Whether you’re looking to control erosion, improve drainage, or enhance soil stability, this fabric can be a game changer. Its lightweight & durable nature makes it perfect for a variety of applications, from landscaping to construction. When buying non woven geotextile fabric, remember to consider your specific needs & the environment in which you’ll use it. By doing so, you’ll be sure to select the right product that will serve your project well & deliver lasting results. Invest in non woven geotextile fabric & enjoy its many advantages!

<<<<< Buy Now from Official offer >>>>>