Civil Engineering Tips & Tricks

Slump Test of Concrete – slump cone for Workability – কংক্রিটের স্লাম্প টেস্ট

Slump Test of Concrete – slump cone for Workability – কংক্রিটের স্লাম্প টেস্ট

A slump test is a research center or at-site test used to gauge the consistency of cement. The slump test shows a sign of the consistency of cement in various groups. The state of the substantial slump shows the data on the functionality and nature of cement. The qualities of cement as for the inclination of isolation can be additionally decided by making a couple packing or passes up tapping pole on the base plate. This test keeps utilizing since 1922 because of the effortlessness of contraption and straightforward methodology. The state of the Slump cone shows the functionality of cement.

Principle of Slump test

The slump value of concrete is just a principle of gravity flow of the surface of the concrete cone that indicates the amount of water added to it, which means how much this concrete mix is in workable condition.

Device for Slump test

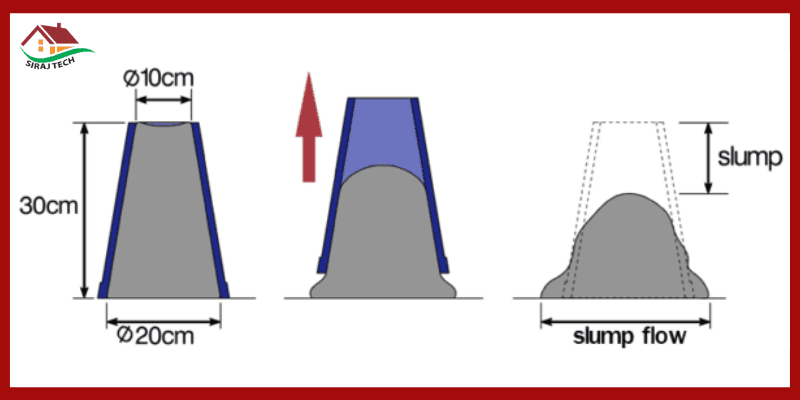

The followings devices are utilized in the slump trial of cement:

Metallic form looking like a frustum of a cone having a base measurement of 20 cm (8 in), top breadth 10 cm (4 in), and stature 30 cm (12in).

Steel packing pole having 16 mm (5/8 in) breadth, 0.6 m (2 ft.) long with the projectile end.

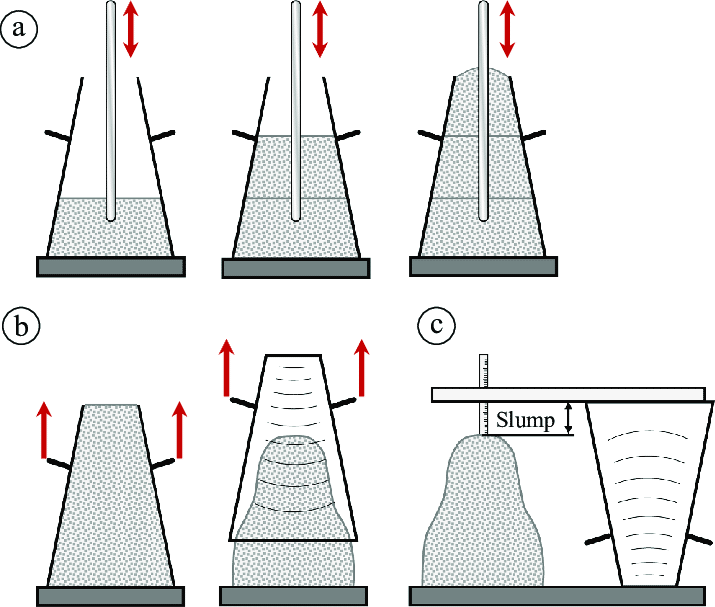

Method of Slump test

During the Slump test following advances are followed:

Above all else, the interior surface of the form is cleaned and liberated from dampness and liberated from other old arrangements of cement.

Then, at that point place the shape on the smooth level, inflexible, and non-absorbant surface.

The form is then loaded up with new cement in four layers with taping each layer multiple times by taping pole, and level the top surface with a scoop.

Then, at that point, the shape is gradually pulled in vertical and eliminated from concrete, so as not to upset the substantial cone.

This free concrete distort all the surface to die down because of the impact of gravity.

That subsidence of cement in the fringe is a slump of cement.

The tallness distinction between the stature of subsidence cement and shape cone in mm is ‘slump worth of cement’.

Recorded slump worth of an example is = … … mm

The improvement of the slump is displayed in fig.3.

Safeguard during test

The inside surface of the form ought to be cleaned and liberated from dampness.

The base plate or surface ought to be liberated from vibrations or stunning.

This test is done soon after examining almost the following 2 minutes.

Utilizations and Drawbacks of slump test

This test doesn’t give great outcomes for extremely wet and dry cement. Additionally, for solid blend, it isn’t touchy. The table underneath shows the different upsides of slumps with the functionality of cement.

Following outline shows the Slump Value of cement for various Degree of functionality for different putting conditions:

| Level of workability | Placing Conditions | Slump(mm) |

| Extremely Low | concrete (individual from concrete by spreading, shallow areas, Pavements utilizing pavers (blender with spreading arrangements) | Compaction factor 0.75 – 0.8 |

| Low | Mass concrete, gently built up piece, pillar, divider, segment segments, trench lining, strip balance (ling divider with more modest width ) | 25 – 75

|

| Medium | Heavily built-up areas in pieces, radiates, dividers, sections. Slip formwork (incline concrete), siphoned concrete. | 50-100 |

| High | Trench fill, in-situ piling | 100-150

|

| Very high | Tremie concrete (cementing in water by utilizing watertight line to pour concrete.) | Flow test.

|

Table: Value of Slump at various levels of Workability

Much exploration shows that for the “exceptionally high” classification of usefulness, the stream test is more reasonable for functionality estimation.

For enormous development projects, a slump test is an extremely helpful apparatus to really look at every day or hour-to-hour variety of the nature of the substantial blend, and by noticing slump perusing, we can undoubtedly change the dampness (water) content and reviewing of cement. Because of that explanation, it is the most well-known technique for tests.

State of substantial droop

At the point when the metal form is eliminated from the substantial cone, the slump takes the accompanying shapes:

Genuine Slump: True state of a slump is just a confirmed slump. This shape is measure as the contrast between the top layer of the cone to the highest point of the slumped concrete.

Breakdown Slump: It shows that because of a high water-concrete proportion, the state of a droop is certifiably not a reasonable measurement. That is to say, concrete is extremely high functionality, for which slump test isn’t reasonable.

Shear Slump: This state of a slump is equivalent to the shear disappointment of soil. This means that an absence of union of the substantial blend fixings. Thus, a new example is taken and the test is rehashed.

Components affecting Slump Cone:

The followings factors impact substantial Slump esteem:

Water – concrete proportion of cement.

The nature of coarse and fine totals, their shape, dampness content, surface, and reviewing.

The utilization of plasticizer, superplasticizer admixture, and the grouping of their blending.

The void proportion of cement and air content of cement.

The hour of the test subsequent to the blending of cement.

Principles for Slump test:

US – standard: In the United States, this test is known as ” Standard Test Method for Slump of Hydraulic – Cement Concrete” and stream the code ASTM C143 OR (AASTO T119).

Joined Kingdom and Europe: The more established norm for the British was first (BS 1881–102). Be that as it may, presently they utilize European standards (BS EN 12350-2).

Indian Standard: Indian standard is: IS 1199-1959

Present-day Technology:

For quick testing, another contraption called ‘K-Slump Tester’ is created. This gadget can quantify slump esteem inside a moment after it is embedded into new concrete. Furthermore, it can likewise quantify relative workability.d of the test.

১০০+ টিনশেড বাড়ির ডিজাইন দেখতে নিচের লিঙ্কে ক্লিক করুন

১০০+ একতলা বাড়ির ডিজাইন দেখতে নিচের লিঙ্কে ক্লিক করুন

১০০+ ২ তলা বাড়ির ডিজাইন দেখতে নিচের লিঙ্কে ক্লিক করুন

Our Services: (Steel + RCC)

- Architectural design,

- Structural design,

- Electrical design,

- Plumbing design,

- Working drawing,

- 3D design, 3D animation

- Landscape design,

- House, Market, Industry & Factory Plan / Master Plan – 2D & 3D

- City Corporation / Pouroshova / Union Approval Sheet

- Estimate

- Project Management, Quality Control

- Construction and supervision

- Soil test and pile

- Digital Survey

আমাদের সাথে যোগাযোগ এর ঠিকানা ফেসবুক পেজে গিয়ে সরাসরি আমাদেরকে মেসেজ দিতে পারেন। ফেসবুক পেজে গিয়ে Text অথবা Voice Record করলে , আমরা ১০০% রিপ্লাই দিব।

You can message us directly by going to the contact’s address Facebook page. If you go to the Facebook page and record Text or Voice, we will give 100% reply.

Email – siraj875212@gmail.com

Phone = 01741454219 ( Imo + Whatsapp + Bip + Viber )

সকল ধরনের বাড়ির ডিজাইন দেখতে নিচের লিঙ্কে ক্লিক করুন

HOUSE-BUILDING AND FACTORY DESIGN

https://sirajtech.org/category/house-building-and-factory-design

বাড়ি নির্মাণ সম্পর্কে টিপস ট্রিকস জানতে লিঙ্কে ক্লিক করুন

CIVIL ENGINEERING TIPS & TRICKS

https://sirajtech.org/category/civil-engineering-tips-tricks